Our Portfolio

These featured projects highlight the scale, quality, and engineering excellence that Abe-Tec (EA) Ltd has successfully delivered in partnership with our valued clients.

IberAfrica 56MW Nairobi South Power Plant Phase II

Project: 56MW HFO Power Plant Installation of 6 Wartsila engines.

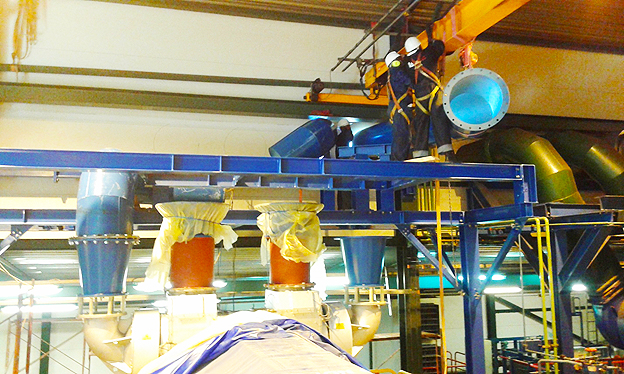

Installation of 6 Wartsila engines, equipment e.g. fuel oil separator, auxiliary module, lube oil module, exhaust gas module, radiator etc.

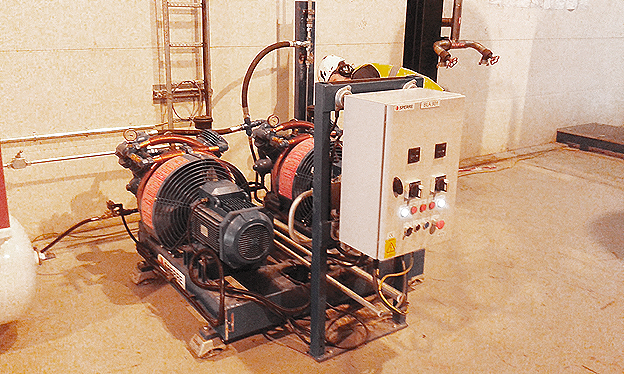

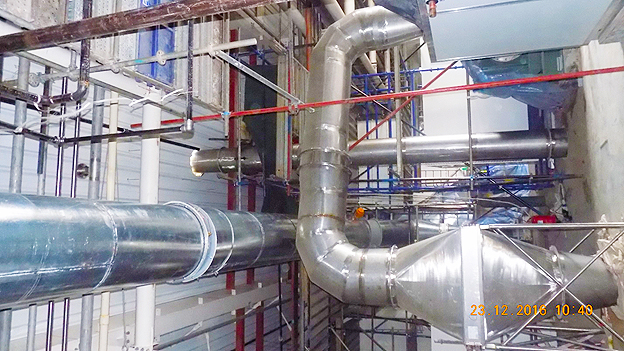

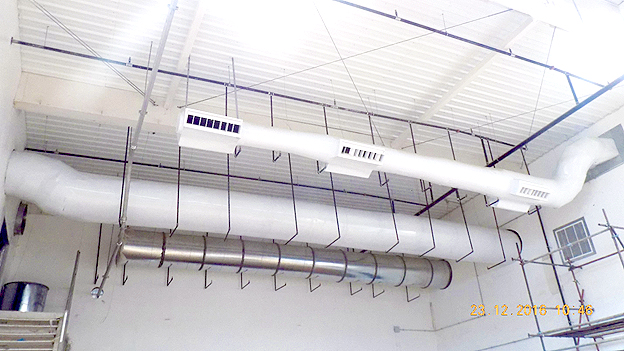

HFO, LFO, Lube Oil piping (carbon steel), water treatment piping (stainless steel), compressed air line and fie water line (galvanised) piping.

Installation of Exhaust Gas Duct

Pipe Bridges and pipe crossovers

pickling and passivation of HFO, LFO and Lube Oil lines

Flushing water lines

Painting of all piping

- Client: Iber6Africa

- EPC Contractor: Socoin, Spain

- Contract: Electrical Installation, Mechanical Erection & Fabrication & Piping

- Start Date: October 2008

- Project Duration: 64 Weeks

119MW Kipevu III Power Plant Mombasa

Project: 119MW Kipevu III Power Plant - Installation of 6 Wartsila engines.

Installation of equipmet like fuel oil separator, auxiliary module, lube oil module, exhaust gas module, radiator etc.

HFO, LFO, Lube Oil piping (carbon steel), water treatment piping (stainless steel), compressed air line and fie water line (galvanised) piping.

Installation of Exhaust Gas Duct

Pipe Bridges and pipe crossovers

pickling and passivation of HFO, LFO and Lube Oil lines

Flushing water lines

Painting of all piping

- Client: Civicon Engineering, Mombasa

- EPC Contractor: Wartsila, Finland

- Contract: Electrical Installation, Mechanical Erection & Fabrication & Piping

- Start Date: July 2010

- Project Duration: 48 Weeks

80MW Power Plant - Gulf Power

Fabrication of Tanks, including 2x5000KL Tanks.

Installation of 10 Wartsila Engines, Eqiupment like Fuel oil separator, auxiliary module, lube oil module, exhaust gas module, radiator etc.

HFO, LFO, Lube Oil piping (carbon steel), water treatment piping (stainless steel), compressed air line and fie water line (galvanised) piping.

Installation of exhaust gas duct, condenser, stack structure and erection of chimney.

Pipe Bridges and Pipe Crossovers.

Pickling and passivation of HFO, LFO and Lube Oil lines.

Flushing of water lines.

Painting of all piping.

- Client: Gulf Power

- EPC Contractor: Wartsila, Finland

- Contract: Electrical Installation, Mechanical Erection & Fabrication & Piping

- Start Date: March 2014

- Project Duration: 43 Weeks

87MW Power Plant Thika

Building Power House and Fuel Treatment house with soundproof sandwich panels.

Fabrication of Tanks including 3x5000KL tanks and 1x200KL Stainless steel tank with other tanks.

Installation of 5 MAN Engines, equipment like fuel oil separator, auxiliary module, lube oil module, exhaust gas module, radiator, etc.

HFO, LFO, Lube Oil piping (carbon steel), water treatment piping (stainless steel), compressed air line and fie water line (galvanised) piping.

Installation of exhaust gas duct, condenser, stack structure and erection of chimney.

Erection of 5x80T capacity boilers.

Installation of turbine.

Pipe Bridges and Pipe Crossovers.

Pickling and passivation of HFO, LFO and Lube Oil lines.

Flushing of water lines.

Painting of all piping.

All electrical works including cabling, installation of panel, cable trays and transformer.

Installation of substation.

- Client: Matelac, Lebanon

- Contract: All Electrical Works, All Mechanical Works & All Piping

- Start Date: March 2012

- Project Duration: 95 Weeks

84MW Power Plant - Triumph Power

Building Power House and Fuel treatment house with soundproof sandwich panels.

Fabrication of tanks including 3x5000KL tanks and 1x200KL Stainless Steel tank with other tanks.

Moving to position and installation of 10 Hyundai Engines, Equipment like Fuel Oil separator, Auxiliary module, Lube Oil Module, Exhaust Gas Module, Radiator etc.

HFO, LFO, Lube Oil Piping (Carbon Steel), Water Treatment Piping (Stainless Steel), Compressed Air Line and Fire Water Line (Galvanized) Piping.

Installation of Exhaust Gas Duct, condenser, stack structure and erection of chimney.

Erection of 10 boilers

Pipe Bridges & Pipe Crossovers

Pickling and Passivation of HFO, LFO and Lube Oil lines.

Flushing of Water Lines

Painting of all piping

- Client: XJ Power, China

- Sub Contractor: Joburg Engineering, South Africa

- Contract: Electrical Installation, Mechanical Erection & Fabrication & Piping

- Start Date: January 2014

- Project Duration: 95 Weeks

Public Utility Corporation Power Plant - Seychelles

16MW Power Plant in Mahe & 4MW Power Plant in Praslin

Installation of 2 Wartsila Engines, equipment like fuel oil separator, auxiliary module, lube oil module, exhaust gas module, radiator etc.

HFO, LFO, Lube Oil Piping (Carbon Steel), Water Treatment Piping (Stainless Steel), Compressed Air Line and Fire Water Line (Galvanized) Piping.

Pipe Bridges & Pipe Crossovers

Pickling and Passivation of HFO, LFO and Lube Oil lines.

Flushing of Water Lines

Painting of all piping

Installation of Exhaust Gas Duct, condenser, stack structure and erection of chimney.

- Client: Wartsila, Finland

- Contract: Electrical Works, Mechanical Works & Piping

- Start Date: July 2015

- Project Duration: 35 Weeks